Three Core Standards for Selecting Servo Robots for Three-Axis Injection Molding Machines in Vietnamese 3C Electronics Factories

In the rapidly expanding Vietnamese 3C electronics manufacturing sector, the injection molding process is a core link connecting upstream and downstream supply chains. However, labor shortages, rising production costs, and the high precision requirements of 3C products such as mobile phone casings and connectors have made the selection of three-axis injection molding servo Robotic Arms a key factor restricting the efficiency upgrading of factories. For European and American purchasers who invest in or provide supporting services for Vietnamese 3C factories, choosing a robotic arm that adapts to local production characteristics can directly reduce operating costs by 30% and improve product qualification rates by more than 90%.

Combined with 500+ project cases of ZHIYI Intelligent Robot in the global 3C injection molding field, this article sorts out 3 core selection standards for three-axis servo robotic arms, and interprets them with actual application cases of Vietnamese 3C electronics factories.

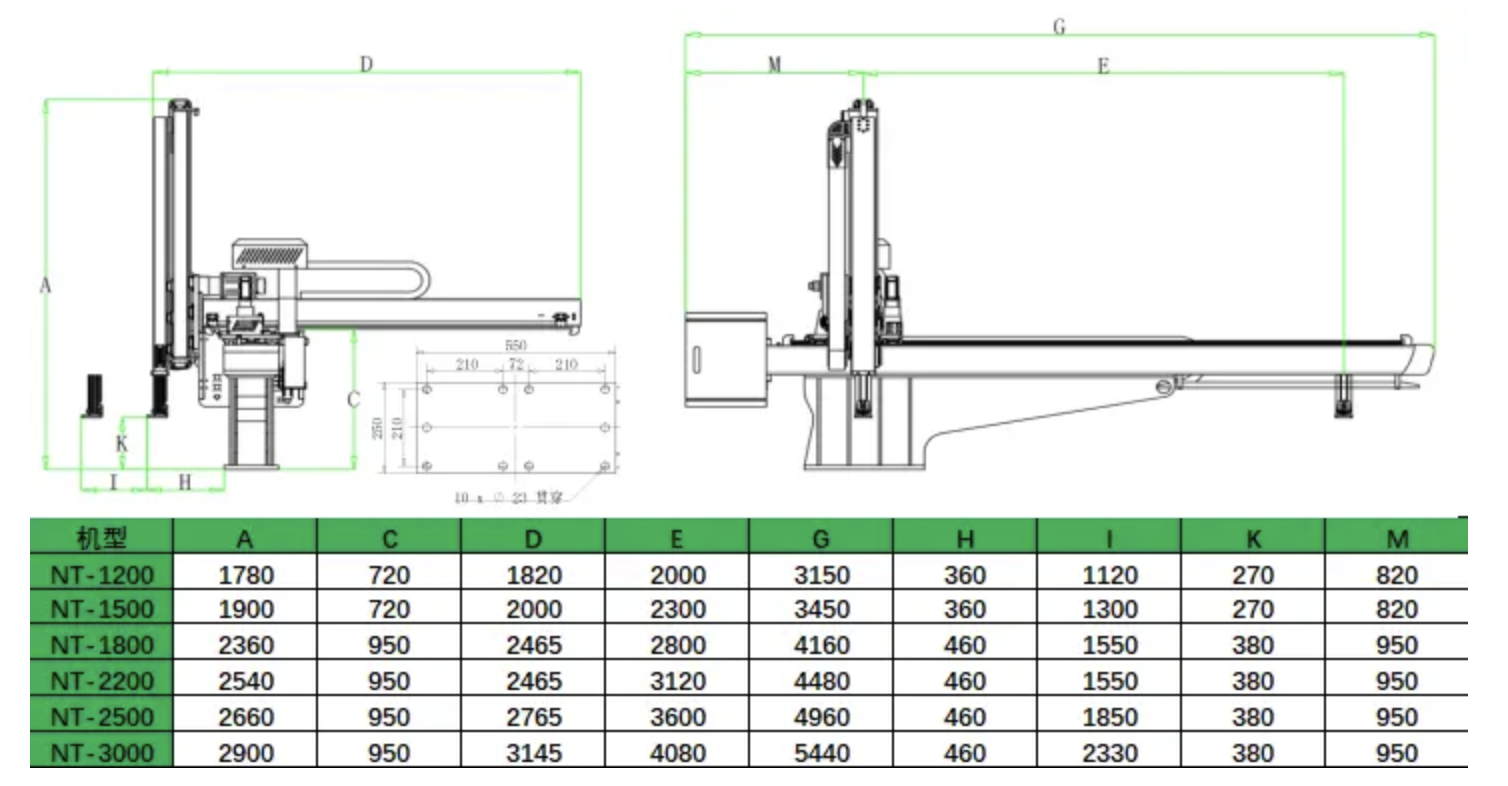

Core Standard 1: Precise Matching of Load Capacity with Injection Molding Machine Tonnage and Product SpecificationsThe load capacity of the three-axis servo robotic arm is not a simple parameter competition. It needs to be matched with the tonnage of the injection molding machine and the weight of the 3C product to reserve a 20%-30% safety margin, which is the key to avoiding equipment idleness and production bottlenecks.

In the Vietnamese 3C electronics manufacturing industry, small and medium-sized injection molding machines (50-150 tons) are mainly used for producing small components such as USB connectors and earphone shells, while large injection molding machines (300 tons or more) are used for processing large products such as tablet computer back shells and notebook computer casings. If a low-load robotic arm is forced to match a large injection molding machine, it will not only fail to complete the mold picking task, but also cause mechanical wear and safety accidents due to overload operation.

ZHIYI Actual Case: Vietnamese Tablet Shell Factory Efficiency Upgrade Project

A 3C electronics factory in Bac Ninh Province, Vietnam, specializes in producing 12.9-inch tablet computer back shells. The original robotic arm has a load capacity of only 20kg, which cannot adapt to the 350-ton injection molding machine and the 32kg complex mold of the product. The mold picking time per unit is as long as 45 seconds, and the product defect rate caused by unstable grabbing is as high as 8%.

After replacing the ZHIYI Bull Head 3-Axis Servo Robotic Arm with a maximum load of 50kg, the factory achieved three major improvements:

The load safety margin reaches 36%, which can easily handle the grabbing and transferring of complex molds;The single mold picking time is shortened to 28 seconds, and the daily output is increased by 25%;The product qualification rate is increased to 99.2%, reducing the rework cost by 18%.

#High-load three-axis servo robotic arm#3C electronic injection molding complex mold adaptation#Vietnamese injection molding machine tonnage matching robotic arm selection.

Core Standard 2: Coordination of Micron-Level Motion Accuracy and Production Rhythm3C electronic products have strict requirements on size tolerance. Taking precision connectors as an example, the dimensional error must be controlled within ±0.005mm . The motion accuracy of the three-axis servo robotic arm directly determines the product qualification rate and production rhythm. The key to ensuring accuracy lies in the linear guide rail and ball screw structure of the robotic arm, as well as the real-time feedback and adjustment capability of the servo system.

Vietnamese 3C factories often face the problem of unbalanced production rhythm due to insufficient robotic arm accuracy. For example, in the production line of charging head shells, if the robotic arm has a positioning error of more than 0.01mm, it will cause the product to be misplaced during the subsequent assembly process, resulting in the shutdown of the entire line for adjustment.

ZHIYI Actual Case: Vietnamese Connector Factory Defect Rate Reduction Project

A foreign-funded connector factory in Ho Chi Minh City, Vietnam, produces USB-C connectors for European and American consumer electronics brands. The original three-axis robotic arm has a positioning accuracy of ±0.02mm, resulting in a product defect rate of 12%, which cannot meet the AQL sampling standard of European and American customers.

After introducing the ZHIYI WKG-1000 Three-Axis Single-Arm Single-Section Robotic Arm, the factory achieved a qualitative leap in precision control:

The robotic arm adopts high-rigidity linear guide rails and precision ball screws, with a positioning accuracy of ±0.008mm, fully meeting the tolerance requirements of connector products;The servo system supports real-time dynamic adjustment, adapting to the temperature change in the Vietnamese factory workshop (25-35°C) to avoid thermal expansion and contraction affecting accuracy;The single-piece production rhythm is shortened from 15 seconds to 5 seconds, and the defect rate is reduced to 1.5%, which successfully passed the second-party audit of European and American customers.

#High-precision three-axis servo robotic arm#3C injection molding defect rate control#Vietnamese electronic component production robotic arm selection.

Core Standard 3: Cross-Equipment Compatibility and Intelligent System IntegrationWith the upgrading of Vietnamese 3C factories to "smart factories", the three-axis servo robotic arm is no longer an independent device, but needs to be integrated with the factory's MES system, injection molding machine, and subsequent sorting equipment to achieve data interconnection and unmanned operation. The key to compatibility lies in the robotic arm's support for multiple industrial communication protocols and the flexibility of secondary development.Vietnamese 3C factories have a mixed situation of new and old equipment. Some old injection molding machines produced in the 2000s still use analog signal output, while new equipment supports Ethernet communication. If the robotic arm cannot adapt to multiple protocols, it will require a lot of transformation costs to achieve system integration.

ZHIYI Actual Case: Vietnamese Comprehensive 3C Accessories Factory Intelligent Upgrade Project

A comprehensive 3C accessories factory in Hai Phong, Vietnam, has 23 injection molding machines of different brands and ages, and plans to build a digital production line. The biggest difficulty lies in the integration of the robotic arm with the factory's SiMDA-MES system to realize real-time monitoring of equipment OEE and production data.ZHIYI provided a customized three-axis servo robotic arm solution for the factory, which has the following advantages in compatibility and integration:

The robotic arm supports more than 200 industrial communication protocols, and the dynamic protocol parsing engine can automatically identify the signal type of new and old injection molding machines, shortening the docking cycle to 72 hours;It is seamlessly connected with the SiMDA-MES system, realizing real-time feedback of parameters such as robotic arm operating status, mold changing times, and product yield;Support the connection with high-speed sorting equipment, realizing the whole process of "injection molding - picking - sorting" without manual intervention.

After the project was put into operation, the factory's equipment utilization rate increased by 30%, unplanned downtime decreased by 50%, and the labor cost per unit product was reduced by 22%, which laid the foundation for building a "lights-out factory".

#Three-axis injection molding robotic arm MES system docking#Vietnamese 3C smart factory automation solution# cross-equipment compatible servo robotic arm selection.

Avoid Pitfalls in Selection: 3 Key Tips for Vietnamese 3C FactoriesDon't only focus on price and ignore safety certification: ZHIYI's three-axis servo robotic arms have obtained ISO9001 and CE certifications, which can meet the safety standards of European and American customers for factory equipment. Some low-cost robotic arms on the market lack certification, which may cause customs clearance risks when exporting products to Europe and America.Don't ignore after-sales service coverage: Vietnamese 3C factories are mostly located in industrial parks far from the city center. ZHIYI provides 24/7 global pre-sales consultation and after-sales technical support, with a response time of less than 4 hours, avoiding the problem of equipment downtime due to delayed maintenance.Don't pursue over-configuration and cause waste: For small 3C products such as earphone shells, it is not necessary to choose a robotic arm with a load of 50kg. ZHIYI can provide customized solutions according to the actual needs of the factory, balancing performance and cost.

ZHIYI: Your Reliable Partner for Vietnamese 3C Factory Automation UpgradingZhejiang Zhiyi Intelligent Robot Co., Ltd. has been committed to the R&D and manufacturing of injection molding automation equipment since its establishment in 2017. With 13 utility patents, 500+ project cases, and an annual production capacity of 2500 units, ZHIYI has provided stable automation solutions for 3C factories in more than 10 countries and regions including Vietnam, Thailand, and Malaysia .Our three-axis servo robotic arms are designed for the characteristics of the Vietnamese 3C manufacturing industry, solving the pain points of labor shortages, low efficiency, and high defect rates. For European and American purchasers who invest in Vietnamese 3C factories, choosing ZHIYI means choosing a cost-effective, high-reliability, and intelligent automation solution.

Media Contact

Company Name: Zhejiang Zhiyi Intelligent Robot Co., Ltd.

Email: Send Email

Country: China

Website: https://www.zhiyirobotics.com/